Construction Welded Mesh Series

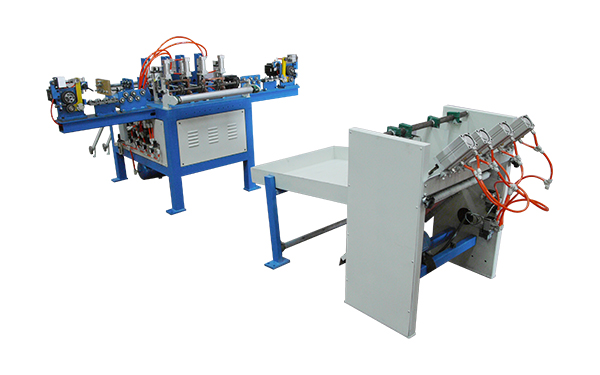

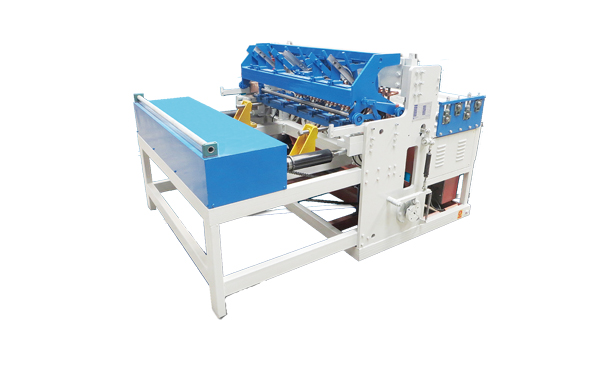

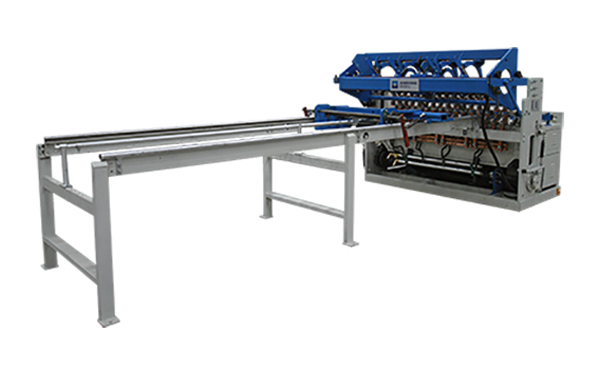

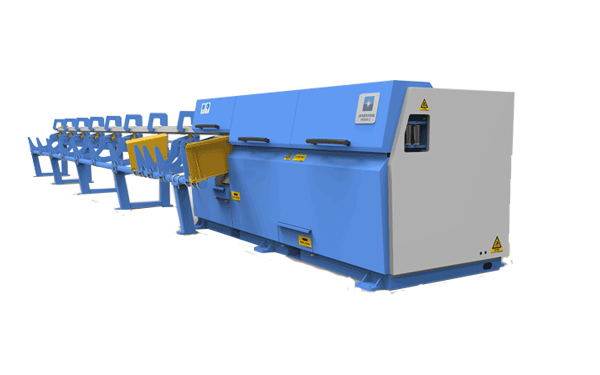

Brick Force Mesh Welding Machine

Introduction and Applications:

1.It is mainly used to produce brick force meshes.

2.Brick force mesh is widely used in construction, hollow wall reinforcement, increase the elasticity, to prevent wall cracks, is a good building auxiliary material

3.Brick force mesh is used for the foundation, wall, etc have higher request for strength and stability of place and the local stress where it is reinforced in the brick and the block.

4.Brick force mesh is used in the reinforcement of the brick and block construction every key points of the cement mortar, so that brick and cement mortar to form an integral whole structure, the maximum absorption stress and vibration, excellent anti-crack performance

Features:

1.The automatic brick force mesh welding production line is a new research and development project designed for some countries in Africa.

2.It works with coil wire feeding, the double work position welding and automatic centerless grinding roll and shear mesh .

3.The welding main engine has the cross servo feeding system, line servo feeding system, welding system, compact structure, small footprint, high degree of automation.

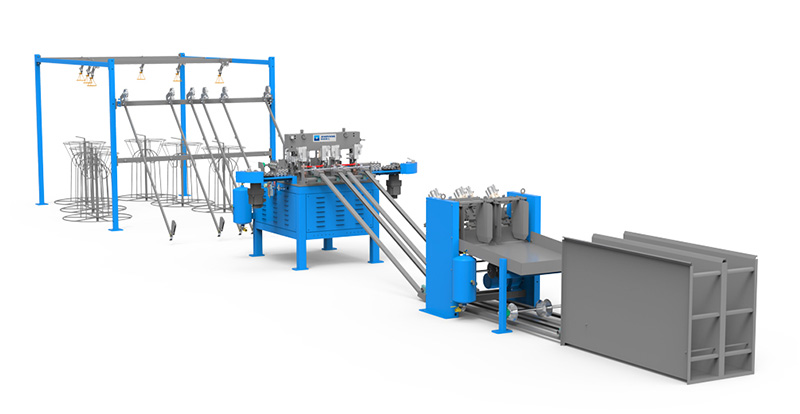

4.Rolling mesh device is mainly composed of the mesh tension, guide, rolling mesh, cutting and dial the mesh device,which has greatly improve the work efficiency, eliminating the need for manual downtime cut mesh rewinding.

5.The payoff reel is a kind of coil wire device with a bearing capacity of 500kg

6.Lead frame is a kind of coil wire into the material guide device, with a branch guide wheel, to prevent the phenomenon of wire dislocation. Also equipped with a feeding detection device to detect lack of wire or overload conditions to ensure that the welding machine to work properly.

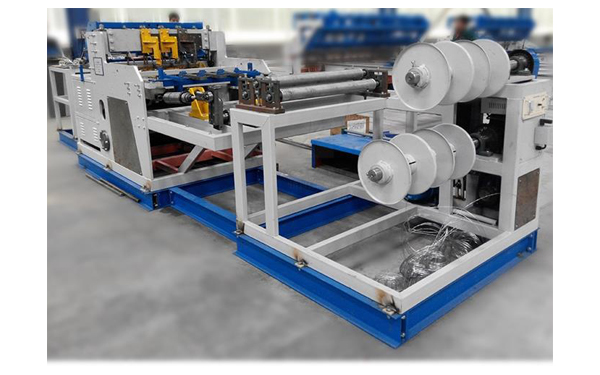

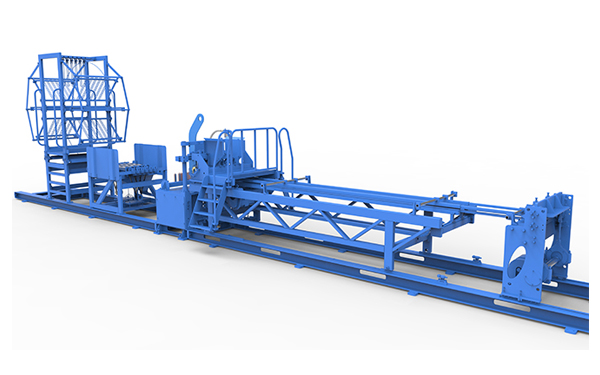

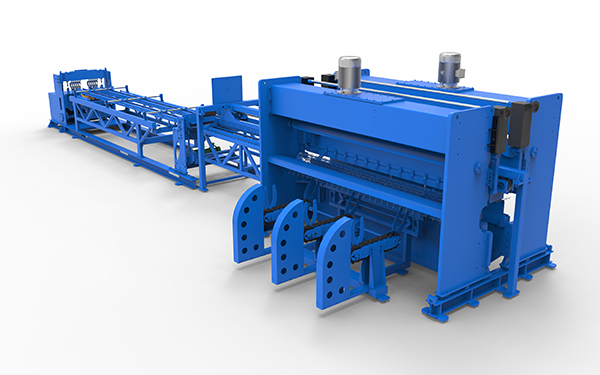

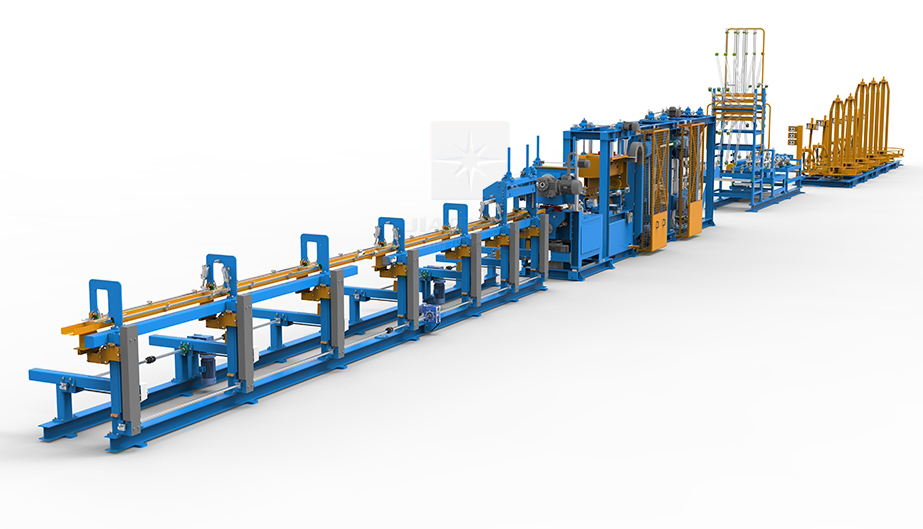

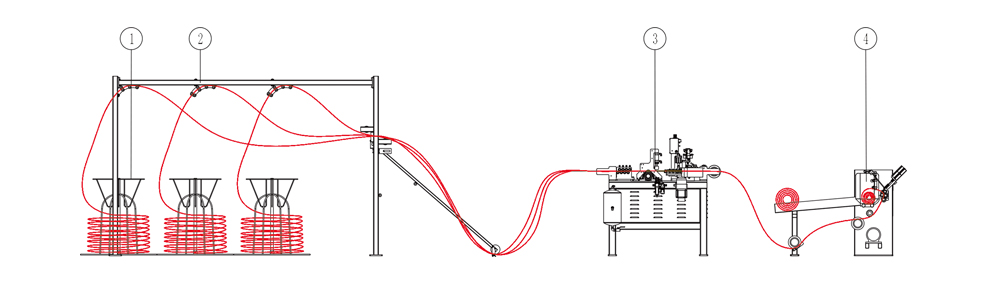

Fully Automatic Reinforcement mesh line I(pre-cut wire) technological processes :

1.Wire payoff 2.Wire guider device 3. Main welding machine 4.CNC mesh rolling machine

Brick Force Mesh Welding Machine Technical Parameters

| Logo | Item | Parameter | Parameter |

| Number of electrodes | 4 | 2 |

| Max. mesh width | 400mm | 300mm |

| Wire diameter | 1.6-3.5mm | 3.5-6mm |

| Line wire space | ≥20mm | 50-500mm |

| Cross wire space | 50-230mm | 50-300mm |

| Electric capacity | 36KVA | 125KVA |

| Welding speed | 80times/min/2roll | 80times/min/2roll |

| Control system | PLC | PLC |

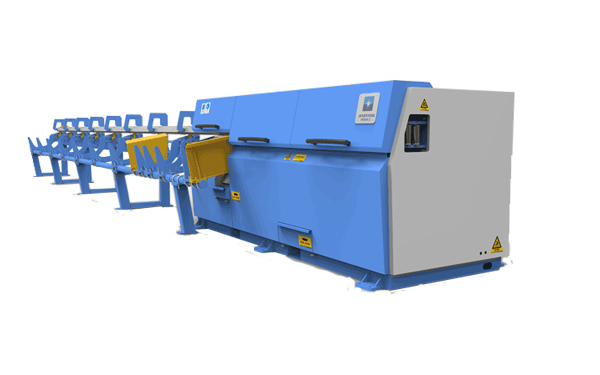

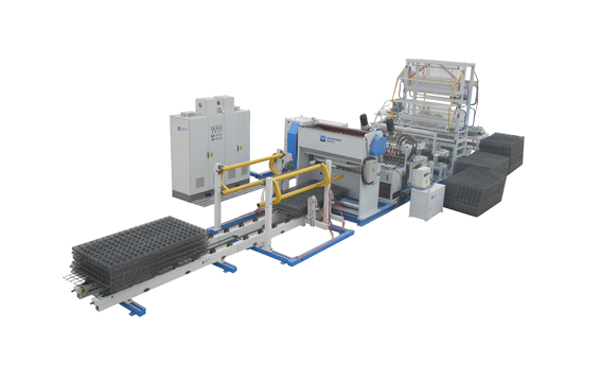

Related Product

Need a quote or contact you?

Please fill in your requirements to the form below and our account manager will contact you as soon as possible.