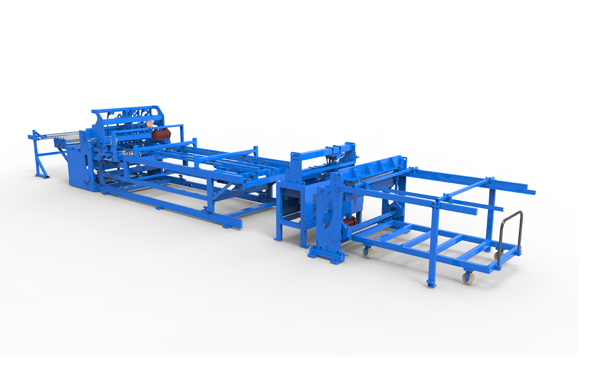

Poultry Cage Welded Mesh Series

Poultry Cage Door Mesh Welding Production Line

Introduction and Applications:

This is the latest designed chicken cage door making machine. Completed production in one step, improve the production efficiency.

Features:

1. Both line wire and cross wire are feed from coil, welding and bending are completed in one step.

2. Servo motor feeding line wire, the size is more exact. Wire feeding pressure is pneumatic.

3. Longer-cross-wire is feed by 1kw servo motor . The mechanism include wire straightening, holding, bending, cutting and welding parts. The holding pressure is pneumatic. The bending and welding pressure also from pneumatic force.

4. The short-cross-wire feeding is pneumatic. It is equipped with straightening, pushing wire, cutting, welding parts. Power of cutting and welding are pneumatic force as well.

5. Equipped with one set CNC wire feed mechanism, to straightening and store wires, make sure the continuous production.

6. Line wires are bend after welding. It’s bend pneumatic. And line wire bending or without bending is customized.

7. The finished cage door is propelled to support shelf pneumatic.

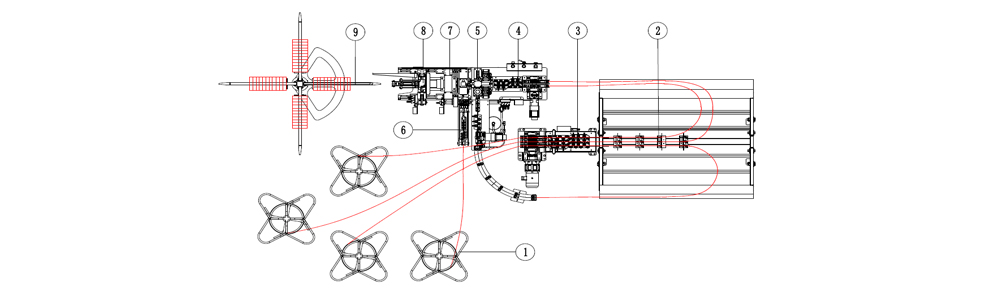

Poultry Cage Barrier Mesh Welding Production Line technological processes :

1. Wire payoff 2.Wire storage shelf 3.CNC wire forwarder 4.Line wire CNC forwarder 5.Welding part 6.Cross wire CNC forwarded 7. Auto. mesh cutter 8. Auto. bender 9.Support shelf of cage door

Poultry Cage Door Welding Production Line Technical Parameters

| Logo | Item | Parameter |

| Number of electrodes | 16 |

| Max. mesh width | 400mm |

| Wire diameter | 2-3mm |

| Line wire space | ≥25mm |

| Cross wire space | ≥25mm |

| Electric capacity | 100KVA |

| Welding speed | 7Pcs/min |

| Control system | PLC |

Related Product

Need a quote or contact you?

Please fill in your requirements to the form below and our account manager will contact you as soon as possible.