Poultry Cage Welded Mesh Series

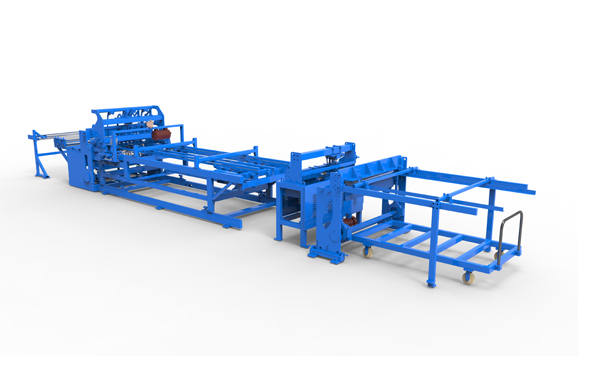

Poultry Cage Mesh Welding Production Line

Introduction and Applications

1.Animal cages production line consists of multiple equipment, continuous production of mesh, simple operation, saving time and effort.

2.It's used to manufacture animal cage mesh.

Features:

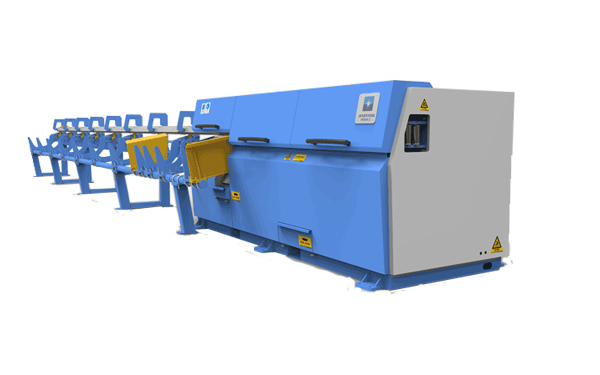

1.Cross wires are pre-cuuting and straightening wire,and line wires are coil wire. It could weld wire mesh sheets and rolls continuously.

2.Main structure of welding machine is the main part that will pressurized the line and cross,power welding, forming the solder joint. Mainly by the welding electrode, welding control system, line and cross wires positioning device

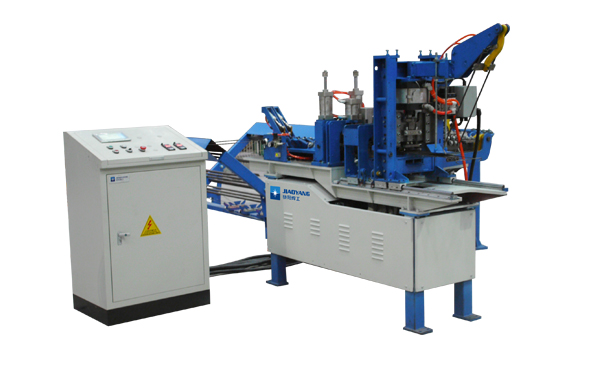

3.Double cross hopper is a two-length or wire diameter for the cross automatic dropping device, installed in the movable pulling mesh rack, with the pulling mesh rack movement.

4.Removable pull mesh rack refers to the rack can be moved within a certain range, mainly by the movable pull mesh rack, pull mesh device, support the pipe of the mesh, rack bottom rail four parts.

5.Welding speed can reach to 80t/min, only need one person to complete the whole process.

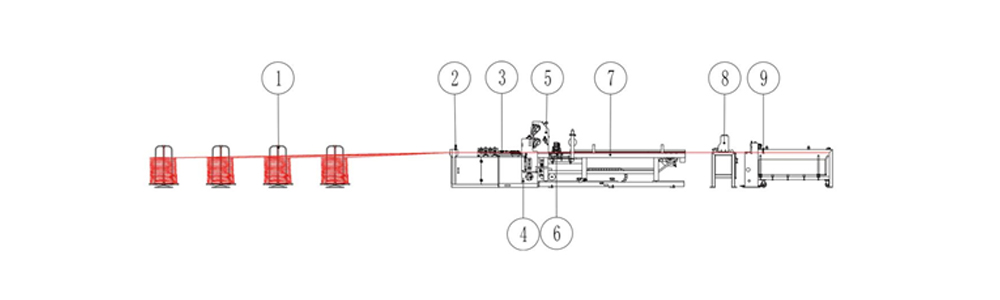

Poultry Cage Production Line technological processes :

1. Wire payoff 2.line wire sensor 3.Line wire straighten unit 4.Main welding machine 5.Cross wire hopper 6.Edge cutter 7. CNC mesh pulling cart 8.Spot welder

9. Mesh cutting machine

Poultry Cage Production Line Technical Parameters

| Logo | Item | GWCD1200(2.0-3.2) | GWCD1600(2.0-3.2) |

| Number of electrodes | ≤16 | ≤16 |

| Max. mesh width | ≤1200mm | ≤1600mm |

| Wire diameter | 2.0-3.2mm | 2.0-3.2mm |

| Line wire space | 25-200mm | 25-200mm |

| Cross wire space | ≥25mm | ≥25mm |

| Electric capacity | ≥160KVA | ≥160KVA |

| Welding speed | 100times/min | 100times/min |

| Control system | PLC | PLC |

Related Product

Need a quote or contact you?

Please fill in your requirements to the form below and our account manager will contact you as soon as possible.